ABOUT US

Nyanga Mover valve is an ISO 9001 certified company who was founded by a team of people with more than 30 years of experience in the supply of industrial valve. During these years we have been adapting to new technologies. All this has allowed us to provide the finest quality products and services to match the need of our clients.

Valve and control engineer

We are a UK based, valve and actuator specialist who provides equipment, support and technical services around the world to many different industry sectors. Despite our wide scope, the company has remained as one of the fastest growing valve and actuator distributors thanks to the tireless efforts of our skilled and experienced staff.

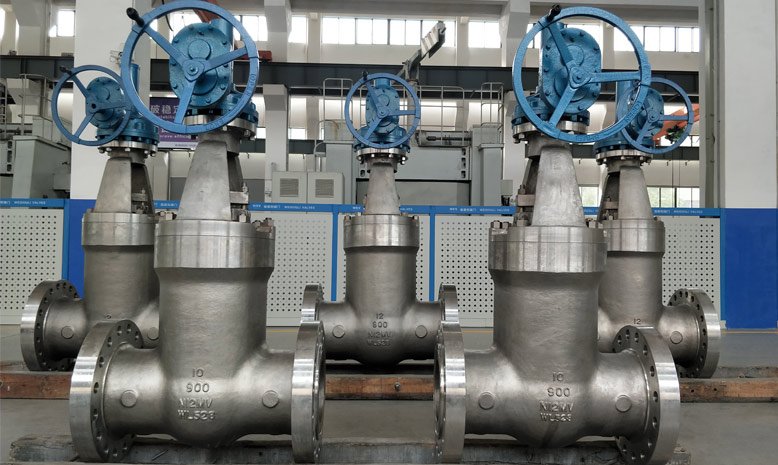

Nyanga valve specialized in valve supplies, including ball valve, gate valve, globe valve, check valves, strainer, plug valves and butterfly valves in carbon steel, stainless steel, duplex stainless and alloy materials. Our products conform to the latest industry standards in accordance to ANSI, ASME, API and DIN.

As an ISO 9001-2015 Quality Approved and certified company, All Valves guarantee a high quality of service from pre-sale sizing & specifying, all the way through to post-sale support. In accordance with our ISO quality management procedures, we test, wherever possible, all products and valve actuator assemblies in-house before shipping, to ensure that our electric ball valves, electric butterfly valves, air actuated ball valves and air actuated butterfly valves reach you in perfect condition, every time.

We offer a complete range of actuated valves, manual valves, pipe fittings, pumps, and controls & can confidently supply products that meet all of your requirements.

Blog

Inconel Valve

An Inconel valve is a valve that is made of Inconel alloy. The Inconel is a nickel-based super alloy. The material has excellent oxidation resistance, corrosion resistance, high strength at high temperatures, and resistance to creep. This material strengthens the valve even at elevated temperatures. The melting temperature of this material is 938 oC which makes its use versatile in a wide range of temperatures. However, Inconel valve has the disadvantage of being heavy since Inconel alloy has high density of 8200 kg/m3. The valve operates manually or automatically. For manual valves, the valve comes with a handwheel or hand lever. The valve operator applies rotary force on the handwheel to open or close fluid flow. Inconel valve manufacturers design the valve to operate with a ball or disc component. The work of the ball or disc component is to close or open fluid flow through the valve. Some of the applications of this valve include oil and gas industry, salty water, marines, petrochemicals and chemicals, pharmaceuticals, among others.

Duplex Valve

A duplex valve is a valve that is made of the duplex steel. Duplex steel is a type of stainless steel material with two phases of the metallurgical structure: the austenite and the ferrite, in almost equal proportions. Duplex material provides better corrosion resistance and higher strength than standard steel. Duplex valves are thus very strong relative to other steel valves. Considering the high melting point of the duplex, this valve has a high thermal resistance and is thus suitable for high-temperature applications such as boilers and power plants. Duplex valve manufacturers recommend this valve for use in high pressure applications due to its high strength. It operates by allowing, throttling, and stopping fluid flow. A disc or ball component is used to control the fluid flow. The valve operates as manual automatic. The manual valve has a handle or handwheel while the automatic one uses pneumatic or electric actuator.

Hastelloy Valve

A Hastelloy valve is a valve that is made of nickel-based alloy known as hastelloy. The two primary elements used to make the hastelloy material are nickel-chromium and nickel-molybdenum. The Hastelloy material has excellent properties relative to other traditional alloys making it one of the preferred alloys used in valve industries. One of the superb properties of this material is its excellent corrosion resistance and high resistance to oxidizing agents and acids. The melting temperature of this material is 1260oC making this valve suitable for use in both low and high temperatures. The material is very strong, which makes the valve ideal for use in high-pressure applications without. However, the Hastelloy valve is very heavy compared to other valves because of the high density of Hastelloy material (8890 kg/m3).

popular pRODUCTS

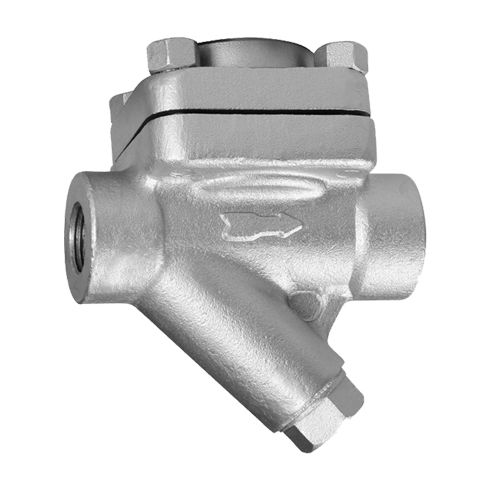

A thermostatic steam trap is a steam trap that works by employing the concept of the temperature difference between steam and cool condensate and air. In this type of trap, steam increases pressure in a thermostatic element. This causes the thermostatic steam trap to close. When the non-condensable and condensate gases in the cooling leg back up, the temperature starts reducing and the thermostatic element contacts to open a valve.

A rubber-lined diaphragm valve is a valve that has its diaphragm lined with a rubber material. This type of valve is used in many applications such as sewage treatment, paper processing, mining minerals, power generation stations, steelworks, and chemical industries. The rubber-lined diaphragm valve has a body made of metal or plastic but a hard and thick rubber lining is used to line the diaphragm.

Orbit valve is a type of ball valve. Orbit valve employs a tilt and turn mechanism that eliminates seal rubbing. Seal rubbing is the main cause of failure in valves such as ball valve, gate valve and plug valve. These valves have strong seals mostly made of metal to enhance their ability to work in challenging and aggressive conditions.